Technology

Nowadays the production of vodka is a complex chemical-technological process that requires the strictest adherence to the recipe and the maximum purity of all ingredients of the future alcoholic beverages.

Water is thoroughly purified and not heat-treated before blending with grain alcohol. It is softened and treated using sodium cation exchange units and reverse osmosis. It is known that hard water contains too much calcium and magnesium salts – “hardness salts”. They can react with alcohol.

The first stage filters are filled with a special resin – cation exchange resin. With its help (as a result of the reaction) calcium and magnesium ions are replaced by sodium ions. Thus, water acquires a certain permissible hardness. If water hardness does not decrease, then the filter is regenerated with salt solution (its capacity is saturated with sodium ions). Then the softened water goes to the reverse osmosis unit. Under excessive – osmotic – pressure, water is forced to pass through the pores of thin membranes in steel cylinders. Water becomes almost completely pure and is ready to be mixed with alcohol.

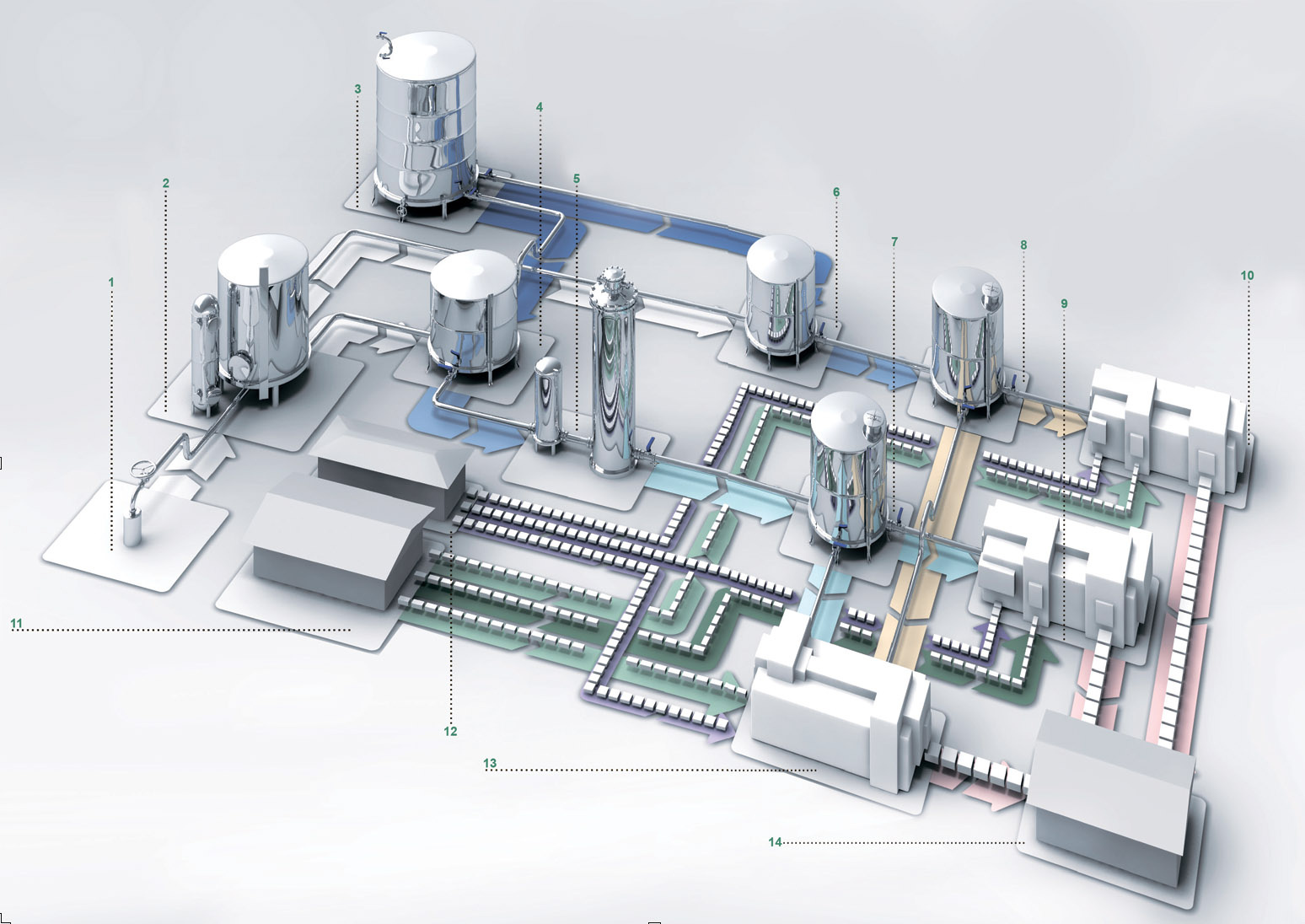

PRODUCTION AND PROCESSING ZONE “BELALCO”

- Artesian well

- Water treatment area

- Acceptance and storage of rectified ethyl alcohol

- Preparation of water-alcohol mixture

- Filtering and processing of water-alcohol mixture

- Liquor production section: preparation and mixing of water-alcoholic extracts, aromatic alcohols, colors and other ingredients of the product

- Blending (bringing vodka to standard alcohol by volume and the choice of ingredients)

- Blend preparation and filtration, liqueur aging, filtration

- Filling and bottling shop (filling and bottling, packaging, labeling)

- Souvenir department of the liquor section

- Finished product release area (storage and release of finished products)

- Export department of the vodka production section

- Main storage

- Packaging storage section.

PROCESS TECHNOLOGY

Technical and technological aspects of Brest distillery are provided by several sections which are part of the offices of the chief power engineer and chief mechanic, engineer for mechanization and automation of the production process. Along with a standard distillery structure, Belalco has unique elements such as, for example, herb growing area. Its products are necessary for the production of special kinds vodka and liqueur.

There are six most important production sites (including the finished product release area and the main storage). The largest site is vodka production site which combines several components of the processing chain and is equipped with necessary and advanced machines and units.

One of the most crucial stages in the production of vodka, for instance, is the stage of mixing alcohol with water followed by the stage of adding other ingredients. After that the mixture is purified.

At the present time the most acceptable methods in modern vodka production are purification methods based on filtration. One of the most effective ways is to purify vodka through a filter using activated carbon. Water is mixed with alcohol with softened treated water in vats/tanks, then it is mixed using special mixers. After that a sample of the blend is taken for strength (alcohol by volume) analysis. If it is more than 40, then water is added, if it is lower than 40, then alcohol is added. That is how the strength (alcohol by volume) is corrected.

Prefilters are filled with the purest quartz sand which is washed twice a month with a reverse flow of vodka (the sand becomes compressed and is partially contaminated), once a year these filters are opened and thoroughly washed with purified water. Successively located filters are filled with sand of different fractions – large, medium-sized and fine, but the mixture comes from top to bottom whereas in charcoal tower (column) filters the mixture comes from bottom to top because the coal must be in suspension. When the mixture passes through the charcoal filters it becomes vodka.

The filtration rate must comply with the technological regulations and cannot exceed forty decaliters per hour. The process should not stop. Minor changes in the content of aldehydes in vodka are possible but in any case it must comply with GOST standards. These changes can result in different flavor of the product. The filtration rate, especially while using activated carbon, is of great importance for the quality of vodka. When vodka comes into contact with activated carbon, fusel oils (25-40% of the total amount in vodka), acetaldehyde (10-17%) and partially ethyl alcohol are partially adsorbed. There is also partial oxidation of ethyl alcohol by oxygen contained in the pores of coal, to organic acids followed by the formation of esters and acetals. The strength (alcohol by volume) of vodka decreases by 0.1-0.2%, its taste and aroma improve. The slower the vodka is filtered and the longer it is in contact with coal, the higher is the quality of the finished product. Further, vodka goes to final purification with sand filters to remove coal microparticles.

Special vats/tanks are used for this purpose. There vodka is mixed with additives measured for each of its types. Then it is checked for strength (alcohol by volume) again. Then vodka is pumped into tanks.

To make an express analysis of the product for strength (alcohol by volume), a liter of vodka is taken for a more thorough analysis done according to the approved method and to the method carried out on the chromatograph. Similar analysis is done prior to the ingredient addition process. It is necessary because if any violations of the strength of vodka appear it is easier to correct them.

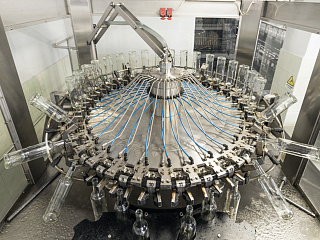

Before bottling vodka goes through another type of filter, through the nozzles of porous membranes which trap microparticles of impurities that can only be detected with the help of high-precision instruments.

Retail containers for vodka are bottles made of semi-white or decolorized glass. Only a few high-quality drinks are bottled in souvenir glass, china bottles and decanters of various shapes.

The glass of the bottles must be thermally stable and chemically resistant. The standards allow permissible deviations of the actual volume of bottles from the nominal one.

Vodka and special types vodka are stored at temperatures from minus 5 to plus 25. At the same time the minimum shelf life is not less than 12 months. The optimum storage temperature for vodka products is 10-20° С, relative air humidity is not higher than 85%. During transportation, as well as in the storage, bottles with vodka must be in an upright position. The products are protected from light, low temperature and precipitation during transportation and handling procedures. The supplier must ensure that the products comply with the standard, provided that the consumer follows storage conditions.

If you look at the scheme of the production area, it is easy to see that there are two directions for finished vodka: to the export department and to the main filling and bottling shop which are shown as separate objects. A special distribution board (a kind of control panel for pipelines) allows you to regulate the flow.

The filling and bottling shop is equipped with three automatic lines of the famous Italian company KOSME – one of the world leaders in the production of specialized equipment for alcoholic beverages industry. Three different types of vodka can be bottled in the shop at the same time. There is a workstation near each line where a visual assessment of the products is carried out. If any slightest deviation from norms appears the defective products are removed from the conveyor. It should be noted that even in the filling and bottling shop alcoholic beverages continue to improve. The so-called 0.2 micron polishing filter is installed directly behind the incoming product pipeline. Absolutely invisible, tiny particles are removed from the liquid and vodka becomes crystal clear.

The liquor section as well as the vodka section is the core of the plant's production area. It includes several specialized departments. The products which are produced here make up more than half of the entire assortment list of the plant. The production includes a full cycle and begins with basic things: alcohol and purified water coming through product pipelines. The most important ingredients for future drinks are prepared here. The syrup department produces sugar and milk-sugar syrups (for emulsion liqueurs, balsams, etc.), and the infusion department produces infusions which are widely used at the plant. As a rule, natural raw materials serve as the basis for them. In addition to herbs, infusions are made on berries, roots, fruits.